How about the potato chips manufacturing process?

Among puffed snacks and various fried snacks, potato chips and fries are popular snacks all over the world and of all ages. Rich flavors, easy to carry, and a variety of eating scenes make potato chips occupy an important position in snacks. So what is the potato chips manufacturing process? How is it produced in a potato chip production plant?

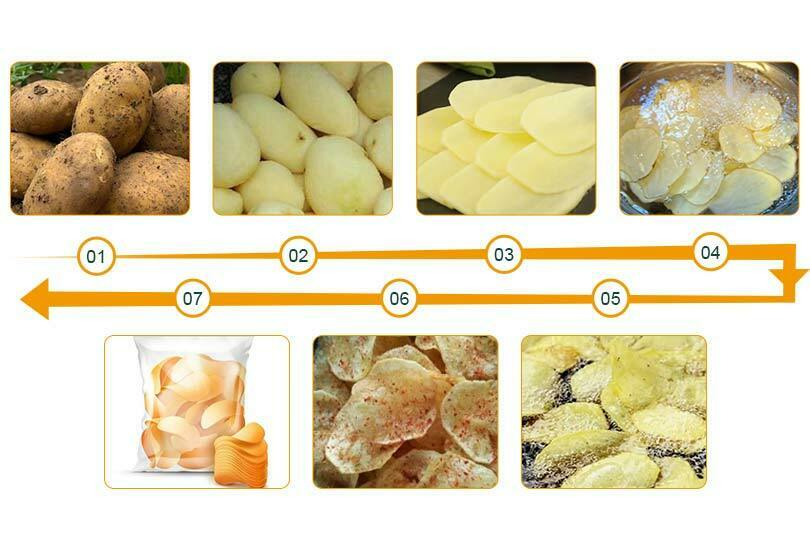

Potato chips manufacturing process

Potato chips are processed into fried potato chips from potato raw materials through a series of steps. The processing of potato chips roughly consists of washing, peeling, slicing, removing starch, dehydrating, frying, degreasing, seasoning, and packaging.

- Washing and peeling is to clean the muddy potatoes and remove the potato skins.

- The slicer cuts the peeled potatoes into potato slices of uniform size. The potato slices cut by a professional potato slicer are uniform in thickness and size. The popular potato chips on the market are generally 3~7mm in size.

- Different types of potatoes contain different amounts of starch. In order to obtain a good taste for fried potato chips, it is necessary to blanch the potato chips to remove the starch from the potatoes.

- After being dehydrated, it can be put into a potato chip frying machine for frying. The frying temperature of potato chips is generally 160~180 degrees Celsius, and the frying time is 2~3 minutes.

- After frying, use a de-oiler to remove excess oil on the surface of the potato chips to maintain a good taste of the potato chips.

- The rich taste of potato chips is obtained by adding different seasonings.

- After seasoning, the production of potato chips is basically over. But in order to facilitate the transportation and storage of potato chips, it is usually necessary to use potato chip packaging for packaging.

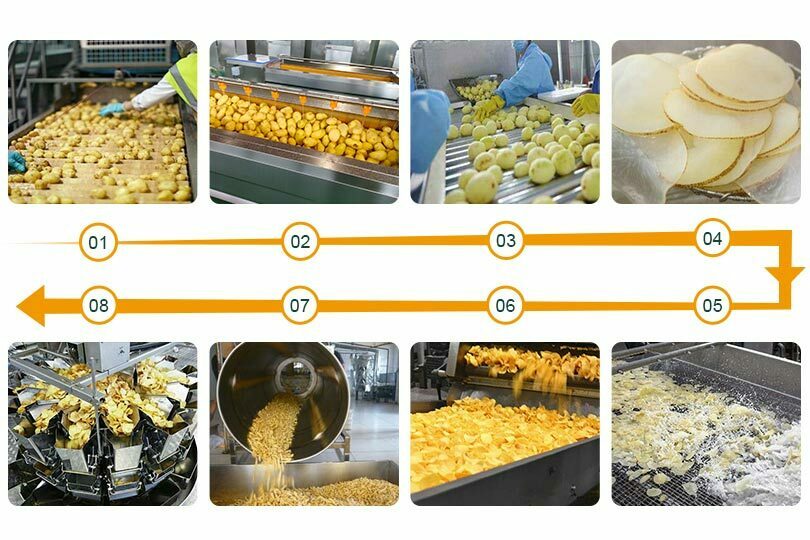

How does a potato chip factory produce potato chips?

The potato chip production plant also follows the above potato chip manufacturing process to produce potato chips. In order to ensure the output of potato chips, potato chip factories usually use specialized potato chip machines to produce. Depending on the degree of automation, potato chip production plants have large and small potato chip factories. And the potato chips processing machine was also exported to Pakistan, Sri Lanka, Turkey, the USA, and other countries.

The difference between small and large potato chip factory processing potato chips

Small potato chip factories have limited funds, so they usually use semi-automatic potato chip production lines to produce potato chips. The semi-automatic potato chip line requires manual operation of the machine, and its output range is 50kg/h~500kg/h. However, the large-scale potato chip processing plant has a large processing output and usually uses fully automatic potato chip production machines to produce. And these automatic potato chip machines realize uninterrupted production through conveyor belts. The production output of the fully automatic potato chip line is 300kg/h~2t/h.