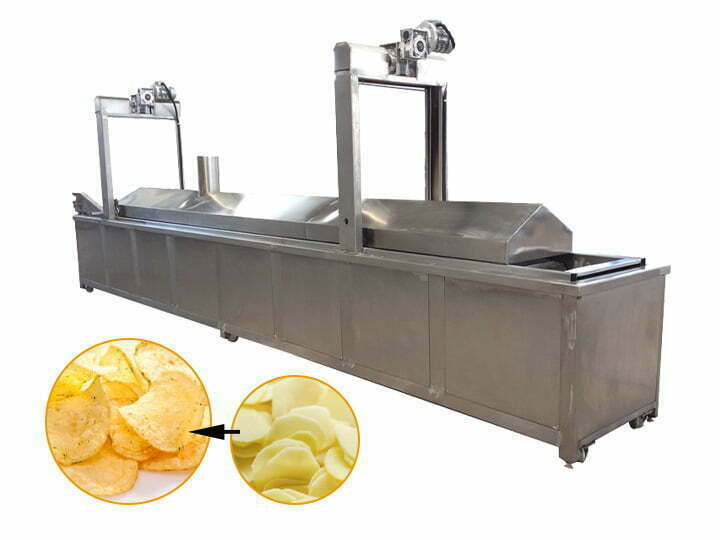

Industrial continuous chips fryer machine

This advanced industrial chips fryer machine has a variable frequency speed control system, which is suitable for frying all kinds of foods (such as tofu, chicken, fish, meatloaf, peanuts, meatballs, potato chips, French fries, etc.). This kind of continuous fryer machine has bright color and solves the problem of excessive acidification of fried food.

Because of its wide range of applications, the industrial potato chip frying machine is welcomed by various food processing plants. The fryer has electric and gas heating methods to meet the needs of different customers. The industrial continuous chips fryer has large processing output, simple operation, and convenient cleaning. It is an environmentally friendly fryer.

Industrial chips fryer introduction

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering, and scraping system

Heating system: electric heating pipe, heat transfer oil, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

Continuous chips fryer machine application

This continuous chips fryer is suitable for frying various foods.

Nuts: broad beans, peanut beans, green beans, and other nuts;

Snack: rice crackers, French fries, potato chips, and other puffed products;

Noodle: rice noodles, cat ears, shaqima, twists, and other noodles;

Meat: diced meat, meatloaf, chicken drumsticks, and other meat products;

Aquatic products: yellow croaker and hairtail;

Soy products: dried tofu and tofu foam.

Industrial continuous potato chips frying machine features

- The water supply valve is located at the lower oil layer, water can be added at any time, it will not affect the frying work, and a check valve is provided. This solves the problem of stopping the water and pouring the oil back into the water pipe during the watering process. problem.

- The bottom water is provided with a temperature measuring device, and the water temperature is clearly displayed. When the temperature is higher than the set temperature, cooling measures can be taken to prevent the boiling of water in advance.

- The oil-water separation surface is provided with an observation device for accurate observation.

- The food residue generated during the drying process can be sedimented into the bottom funnel by filtration of water and discharged through the sewage outlet, thus achieving the function of filtering oil without wasting oil.

- This continuous fryer machine with a double-layer mesh belt avoids product floating and makes food frying more uniform.

Advantages of mesh belt industrial chips frying machine

- With the continuous fryer machine with an automatic control system, the temperature can be set free from 0-300 degrees;

- Oil-water mixing process design, saving 50% of oil than ordinary frying machine;

- Multifunctional, don’t need to change the oil to fry another food, no fumes, no odor, save time and environmental protection;

- Advanced and efficient heating system, the oil and water interface part uses the ventilation tube to dissipate heat, which greatly improves the time of the oil.

- Heating the upper part of the oil and cooling the lower layer, Avoiding the water temperature it is too high, The oil and water are discharged separately, it is easier to remove the food residue and change the oil.

Parameter

| Model | Power | Capacity | Size | Weight |

| TZ-LX3500 | 80kw | 500kg/h | 3500*1200*2400mm | 1000kg |

| TZ-LX4000 | 100kw | 600kg/h | 4000*1200*2400mm | 1200kg |

| TZ-LX5000 | 120kw | 800kg/h | 5000*1200*2400mm | 1500kg |

| TZ-LX6000 | 180kw | 1000kg/h | 6000*1200*2400mm | 1800kg |

| TZ-LX8000 | 200kw | 1500kg/h | 8000*1200*2600mm | 2000kg |

Batch VS Continuous chips fryer

An intermittent fryer is also called a batch fryer. Before frying the next batch of materials, it needs to fry this batch first. The continuous potato chip fryer can continuously fry potato chips. There is no need to wait until the last batch of potato chips is fried to fry the next batch.

In contrast, the batch chips frying machine has a wide application. This is because the intermittent fryer is low in price, low in frying technology, and suitable for small-scale production and low maintenance costs. But the continuous potato chip fryer also has its special advantages. The continuous fryer removes crumbs and other frying by-products during the frying process, so it has a good filtering effect. In the batch frying system, the original heat is caused when putting in the product, so it needs a longer frying time. However, continuous frying systems do not have this problem. In addition, the continuous potato chip frying machine maintains a consistent frying temperature and time during the frying process, which also brings certain benefits to the appearance, flavor, organization, and shelf life of the product.

Electric heating VS gas heating industrial chips fryer

The heating pipe of the electric heating fryer is installed in the heat-conducting oil layer, and it does not directly contact the food. The oil is used to increase the temperature by absorbing the heat of the heat transfer oil, so as to realize the function of fried food. Therefore, it can prevent the edible oil from scorching the heater and cause the edible oil to age rapidly, and prolong its life of the edible oil. The heating tube of the electric fryer is completely sealed and has high safety performance.

The industrial gas chips fryer adopts a high-efficiency Riello brand burner, which has sufficient gas combustion and effectively controls the oil temperature. The combustion pipe is made of high-temperature resistant 304S material, which improves the service life of the equipment. The pipeline adopts the M-type integrated combustion pipeline, which abandons the traditional multiple thin pipelines, fully collects heat, improves the gas utilization rate, saves costs, and improves product quality. A fully automatic gas fryer is suitable for medium and large food processing plants.