In the UK, Scotch eggs, as a traditional British snack, require a stable frying temperature and precise time control to ensure consistent color and texture.

Taizy's customer is a British food processing company that supplies Scotch eggs to local retail and catering channels. To expand production, the customer ordered a reliable electric fryer machine that meets British industrial electricity standards and can handle relatively large and heavy products.

Our client contacted us through our website, and during our subsequent technical discussions, they clearly outlined the following requirements:

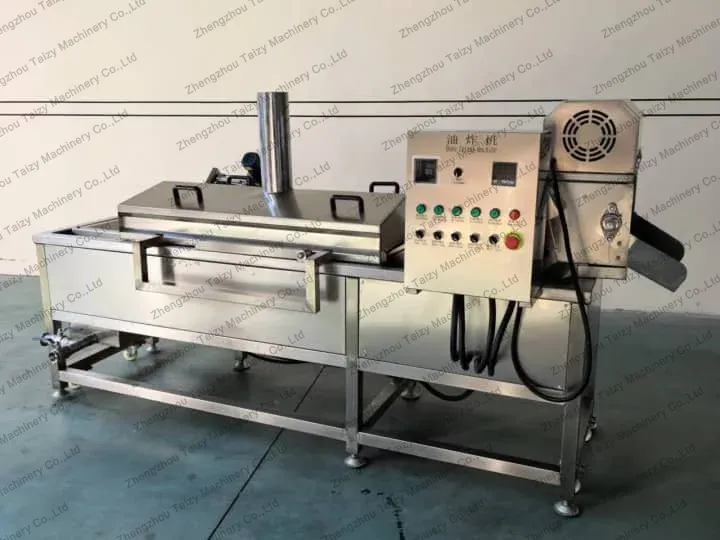

Based on the customer's application requirements and production environment, we provided a 2.5-meter-long electric continuous fryer, specifically designed for processing Scotch eggs.

| Machine | Parameter |

| Electric frying machine | Heating method: Electric heating, equipped with an automatic slag removal system Frying length: 2.5 meters Conveyor belt type: Mesh belt Conveyor belt width: 400 mm Voltage: 400 V / 50 Hz / Three-phase Total power: 48 kW Conveyor speed: 0.024 meters/minute Frying time: 7 minutes Machine dimensions: 2500 × 1000 × 1700 mm Bahan: baja tahan karat 304 Mobility: Equipped with universal wheels |

After negotiation, we finalized the project plan and began production after receiving the deposit.

The entire frying line is delivered as a turnkey system, with the fryer fully tested before shipment and the piping, pump connections, and electrical interfaces pre-installed.

The equipment has completed trial runs after commissioning, and the electric fryer has successfully integrated seamlessly with the customer's production line. Our factory workers cleaned and fixed the equipment before final packaging and sealing, ensuring all components were properly prepared for transport.

Because the fryer machine is mostly assembled before being packaged, our customer only needs to connect the power supply on-site to begin production, which makes it an ideal solution for food processing companies seeking quick installation and reliable operation.

If you are interested in this frying line, please click the link below for more detailed information: Industrial continuous chips fryer machine.

If you want to start your own fried food business or expand your production line, please contact us!